To put it simply, a counterflow wort chiller will be more efficient at cooling in both speed and also due to it being able to transfer to your fermenting vessel simultaneously. For the full explanation as to what is going on during cooling with each type of chiller, see below;

What is a chiller and why is it used in the brewing process?

A chiller is a device that uses a cooling solution to lower the temperature of another solution without the two solutions mixing this is a heat exchange

Heat exchange: is the process of one substance lowering its own temperature by passing its heat onto another substance. The greater the difference the temperature between the two substances the faster the heat will travel from the hotter substance to the cooler substance.

In the beer brewing process, the Wort is boiled for an hour, this is to:

- sanitise the solution to ensure there are no micro-organisms living in the wort

- Concentrate the wort, when sparing we add more water than is needed this is to ensure as much sugar as possible is extracted from the grains. Because we are already boiling for reason 1 we can boil off the excess water to concentrate the sugars to where we want them to be.

- When hops are added at boiling and near boiling temperatures. The alpha acids in the hop oils undergo a chemical change to isomerized alpha acids. These iso alpha acids have very good antibacterial properties and provide bitterness which balances the sweetness from beer residual sugars and alcohol sweetness.

After the wort has been boiled the temperature needs to be reduced so to provide a comfortable environment for the yeast to consume the sugars and produce alcohol. There are two main types of chillers that are used by brewers:

- Immersion chillers

- Counterflow chillers

Immersion chillers

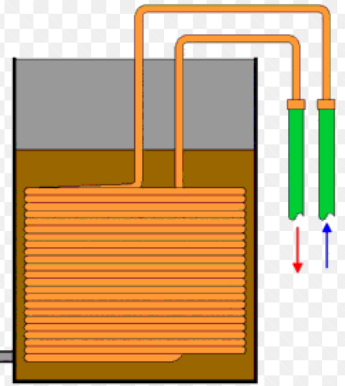

Immersion chillers are large coils of either copper or stainless steel tubing. These two materials are chosen because copper easy to shape and has very high thermal conductivity meaning its very good at transferring heat from once substance to another. While stainless steel is a good conductor, but it is cheaper and much more durable than copper. The reason they are coiled is to maximise the surface area contact between the metal and the wort to be cooled.

These tubes are then immersed in the boiler and cool water is then run through the inside of the coiled tubing. As the cool water travels through the coil it picks up the heat form the hot wort and is carried outside of the boiler, thus cooling the wort in the boiler.

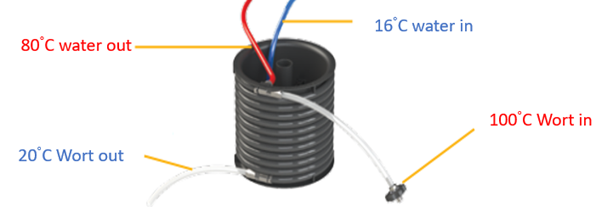

1000C Wort in below

Blue: 150C H2O in

Red: 950C H2O out

Counterflow Chillers

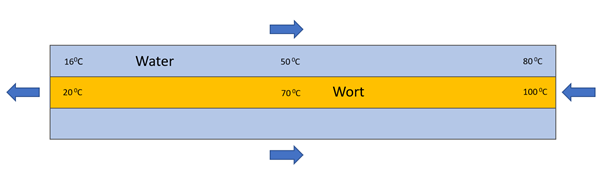

Counter flow chiller work in a similar to immersion chillers that they are mostly made of either copper or stainless steel. However, they are different in how they work, in the immersion system the hot wort remains static in the boiler. So, the area of wort next to the coils cool very quickly, then the cool wort must diffuse with the rest of the hot wort in the boiler to cool it. Where as counterflow chillers are known as a dynamic system. They pass the wort though tubes or between plates while the cooling liquid passes though separate tubes or plate that share a wall with the tubes or plate that contain the wort. These two solutions travel in opposite directions to maximise the heat exchange between the two solutions.

Performance Between Immersion and Counter flow chillers

Heat exchange is depicted by the formula:

Q = h x A x ΔT

- Q = energy (heat) Flow in Watts (W). This can be thought of as cooling power.

- h = overall heat transfer co-efficient (W/(m2 x 0C)). This is how well heat is transferred from the first substance to the next.

- A = Heat transfer area. The surface area of the tubing exposed to the hot wort

- ΔT = temperature Difference in 0 the number of degrees between the hot wort and cooling water

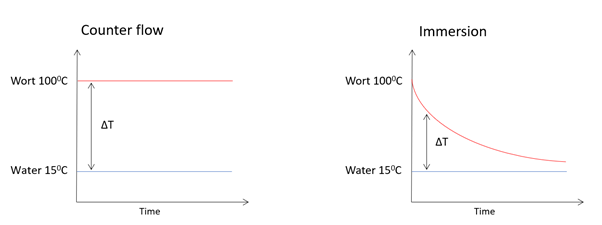

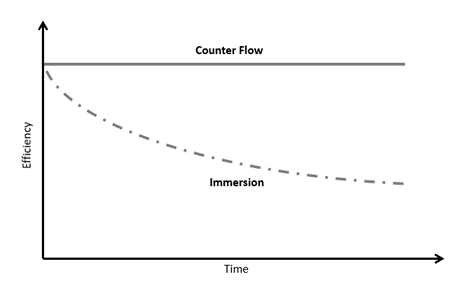

If we have two systems the counterflow and immersion, made of the same material with the same tube lengths and diameter therefore surface area then we have the two graphs below.

Because the with the counterflow chiller the wort only comes in contact with the cooling once the ΔT remains large (1000C wort and 160C water). Whereas with the immersion chiller the whole mass of wort cools so as the wort cools the ΔT gets smaller. This in turn makes Q smaller so we have the graph below:

Benefits of the counterflow chiller

- For the same system it will take less time and less water to cool the same volume of wort.

- With counterflow chillers they are used to cool wort inline while transferring wort from the boiler to the fermenter. This saves time as it turns a two-step process with an immersion chiller (first cool, then transfer).

- It is a sanitary system. Wort at 1000C is sanitary and as the wort is cooled and transferred it is not exposed to the environment where microorganisms may inoculate the wort.

Benefits of the Immersion chiller

- When the surface area is significantly increased to the point where surface area overcomes the limitations ΔT then the immersion chiller can be an very effective and fast way to cool wort.

- To produce an immersion chiller requires less components and is easier to produce so the cost of the final unit is cheaper.

- Immersion chillers can be used to cool any open toped system and does not require a pump.

Limitations of Counterflow chillers

- Counterflow chillers are much more expensive to produce and therefore have a higher end cost.

- Require and system with adequate pumping and filtration capability to transfer the wort through the counterflow chiller to the fermenter.

- Require periodic specialised cleaning due to wort traveling inside the tubing.

Limitations of Immersion chillers

- Until the immersion chiller has a high enough surface area and resulting cooling time, that is faster than a system with a pump can pump its contents through a counterflow chiller to the fermenter, then the immersion chiller will always be slower at cooling and require more water than the counterflow chiller.

- Immersion chillers always require a two-step process for first cooling then transferring. Which unless this takes less time than the counterflow cooling and transferring at the same time. Then this costs more time than the counterflow chiller. The two-step open system also leaves the wort open to contamination (this is low but is still a consideration).

- Require a higher level of general cleaning due to coming in contact with more hop matter and trub in the boiler.