This article will go through the different types of colour units where they are used and how they relate. Then how the Grainfather community app calculates the estimated beer EBC.

Lovibond(°L)

Created in 1883 by J.W. Lovibond (Palmer, 2017). The Lovibond scale was originally a system of glass slides of varying shades and wort was assigned a colour based on matching the wort to a combination of the slides. This system was later modified to a 52 series Lovibond scale which is the Common measure use for malt. This is done by conducting a congress mash then measuring the colour of the resulting wort. The limitation of this system is that it relies on human colour perception between two items.

Standard Reference Method (SRM)

The standard reference method was developed by the American Society of Brewing Chemists (ASBC) in the 1950s by measuring the absorbance of wort (1/2” curvette sample) by UV-Vis Spectroscopy at 430nm. The British adopted a similar method but measuring the absorbance at 530nm (Daniels, 1996). This system was developed to approximate the Lovibond scale, and are approximately equal for most of their scales. However, as the colour darkens, the light cannot pass as easily through the sample in the UV-Vis spectroscopy. Therefore, the sample must be diluted and then the absorbance scaled to give a result for the undiluted sample. (Palmer, 2017)

European Brewing standard (EBC)

This method is relatively recent in its adoption and is very similar to the SRM method. However, the sample size of the wort used for measuring the absorbance at 430mn is much smaller (10ml). (Daniels, 1996). Note that EBC value before 1990 were measured at 530nm and are not directly comparable to SRM.

Colour Conversions

As all three of the above methods are common in the brewing industry, the formulas for calculating the conversions are as follows:

|

Conversion |

Formula |

|

SRM From EBC |

SRM = EBC x 0.508 |

|

EBC From SRM |

EBC = SRM x 1.97 |

|

SRM from Lovibond |

SRM = (1.3564 x °L) - 0.76 |

|

Lovibond From SRM |

°L = (SRM + 0.76)/1.3546 |

Colour Calculation

Colour calculation is a fundamental principle for beer formulation, Lovibond, SRM and EBC are all scales used to quantify colour (Mallett, 2014).

Malt Colour Units (MCU)

Malt colour units are the relative measure of the amount of colour being contributed by the grains in a recipe. To calculate the MCU rating for grain in a recipe, you take the mass of the grain multiplied by the Lovibond value (Daniels, 1996).

To then predict the SRM colour for a beer you add together the MCU for each grain in a recipe, then divide by the batch volume. Some other calculators use the fermenter volume for the calculation. However, since there is no change in colour concentration in the process of transferring wort to the fermenter the volume used in the Grainfather app is the post-boil volume rather than the fermenter volume like other brewing softwares.

*G1=Grain one from the recipe

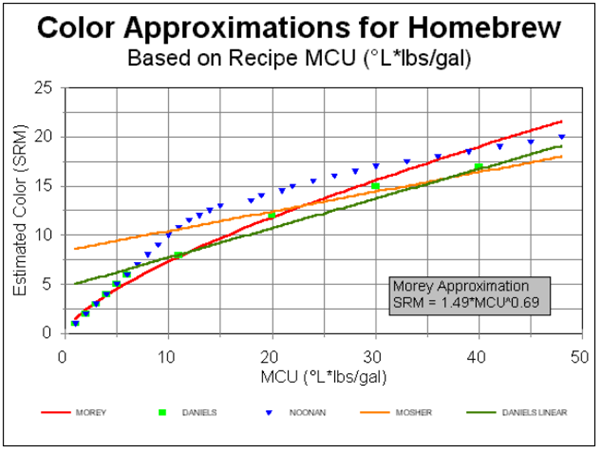

This system works very well until the MCU is greater than 15, which with many speciality grains is quite common. Therefore models needed to be created to best match the real-world results. Liner models were proposed by Ray Daniels (Daniels, 1996) and by Randy Mosher (Mosher, 1994) as seen in the table and graph below, but the issue with these models is that it predicts a minimum SRM value. Which creates issues when using no and very light coloured malts and adjuncts which result in beer styles below the minimum SRM value from these equations. Because of this the Grainfather app uses the Morey equation (Morey, 2015) to determine the SRM then provides the EBC based on the conversion from SRM to EBC above.

|

Source |

Equation |

|

Traditional |

SRM = MCU |

|

(Daniels, 1996) |

SRM = (0.2 x MCU) + 8.4 |

|

(Mosher, 1994) |

SRM = (0.2 x MCU) + 4.7 |

|

(Morey, 2015) |

SRM = 1.49 x MCU0.69 |

Figure 1 (Morey, 2015)

Other factors that affect beer colour

The malt colour is not the only factor that affects the final beer colour other factors like; boil time heating method, hopping rates, yeast flocculation, clarity of the beer sample and oxidation also impact beer colour. These factors are significant enough and variable enough based on brewing practices that the final beer colour can be up to +/- 20% of the calculated beer colour (Palmer, 2017).

Conclusion

This article covers the equations and sources for estimating the final beer colour. However, since there are many other factors that significantly affect the final beer colour that cannot be taken into account in the equation. The best way to be certain of a final beer colour is to have beers produced on a system tested for colour then use these beers as a reference when developing new recipes for that system. “These tools are not the end, they are the means to an end, and the proof is in the beer” (Palmer, 2017).

References

Daniels, R. (1996). Designing Great Beers. Boulder: Brewers Publications.

Mallett, J. (2014). Malt - A Practical Guide from Field to Brewhouse. Boulder: Kristi Switzer.

Morey, D. (2015, June 07). Approximating SRM Beer Color of Homebrew Based on. Retrieved from babblehomebrewers: https://babblehomebrewers.files.wordpress.com/2015/06/estimating-beer-color.pdf

Mosher, R. (1994). The Brewer's Companion . Seattle: Alephenalia Publications.

Palmer, J. J. (2017). How to Brew 4th Edition. Boulder: Kristi Switzer.