This article discusses the theory, calculations, and method used by the Grainfather community app to calculate the original gravity (OG) and the final gravity (FG) for a beer recipe.

Gravity

Gravity refers to the density of the solution. In wort, we are dealing with two items contributing to the overall density of the solution. The first is water, which makes up greater than 90% of the solution, which has a density of 1.000, and the second is sugar from the malt. Sugar is a larger heavier molecule than water, and, therefore, when sugar is dissolved in water, the density of water is increased. In beer, there is a third contributor, ethanol produced by the yeast ethanol is lighter than water with a density of 0.789. Therefore during fermentation, the sugar is consumed, and ethanol is produced, lowering the overall density of the solution. The Original Gravity refers to the gravity of the wort pre-fermentation and the Final Gravity refers to the Gravity post fermentation.

Sugar contribution of ingredients

Many ingredients can contribute fermentable sugars to the wort which in turn can be fermented by the yeast into alcohol. How much fermentable sugar an ingredient can contribute to the wort is measured in Points/pound/Gallons (PPG), for ingredients that are fully soluble in water like honey, sugar, lactose and malt extract. This is the density when 1 pound of the ingredient is dissolved in 1 gallon of water. (Daniels, 1996)

eg Cane sugar sucrose, 1lb in 1 gal of water has a density of 1.046 PPG = 46

With malts it is a little different because malt is not fully soluble in water due to the approximately 20% by weight of husk, insoluble proteins and starches. Maltsters conduct a congress mash and accurately measuring the volume and gravity give a value reported as a percentage extract (%FGDB). Because sucrose yields 100% of its weight is it is used as a reference when calculating the PPG of malts. We take the %FGDB of the malt and multiply it by the PPG of sucrose. (Palmer, 2017)

e.g. 2 – row malt could have a %FGDB of 80.7%

0.807 x 46 = 37 PPG

Calculating Gravity units

With the weight and the PPG of the ingredients used then the gravity units (GU) can be calculated by multiplying the PPG by the weight of grain used

3.5lb of pale ale malt PPG of 37 and 2lb of wheat malt PPG 36

3.5 x 37 + 2 x 36 = 201.5 GU

Then the Recipe Potential Original Gravity can be calculated by multiplying the GU by the post-boil volume in gal. The reason post-boil gravity is used is that when transferring to the fermenter their maybe loss of wort but there is no change in gravity during a transfer.

201.5 / 5gal = 40.3 GU = 1.040

Mash efficiency

The above calculation works when the mash is 100% efficient. However, this is never the case in conventional brewing. Therefore, when first using a new system or brewing practice it is best to work out the efficiency to then use when developing recipes for accuracy. (Daniels, 1996)

If we use the same example as above our recipe potential GU is 201.5 but when put in practice 5gal of 1.036 wort was collected.

1.032 = 32 GU = 32 x 5 gal = 160 GU

Mash Efficiency = Total Gravity of wort / Total potential gravity of grains = 160/201.5 = 79.4%

With a mash efficiency of 79.4%, it can be applied to the recipe potential OG to give the estimated OG for that recipe on that equipment with that brewing style.

40.3GU x 79.4% = 32 GU = 1.032 the estimated OG we round to

Calculating estimated Final Gravity

When calculating estimated final gravity three variables come into play; Yeast attenuation, Mash temperature and Ingredients that add increase the density of the wort but are either partially or not fermentable by the yeast, like lactose. These points are calculated separately and added to the OG and FG at the end.

Yeast attenuation is the percentage of sugars in the wort the yeast typically consumes. Most yeasts have a range of attenuations for the Grainfather Recipe creator before yeast is added to the recipe it takes a default of 75% attenuation. When yeast is added the recipe creator takes the middle of the range obtained from the yeast lab as the value used to calculate the estimated FG. If multiple yeasts are used the recipe creator uses an average of the yeast’s attenuation. If we have an OG of 1.032 and using yeast with an average attenuation of 75% then:

FG = OG - (OG -1) x Attenuation = 1.032 -(1.032-1) x 0.75 = 1.008

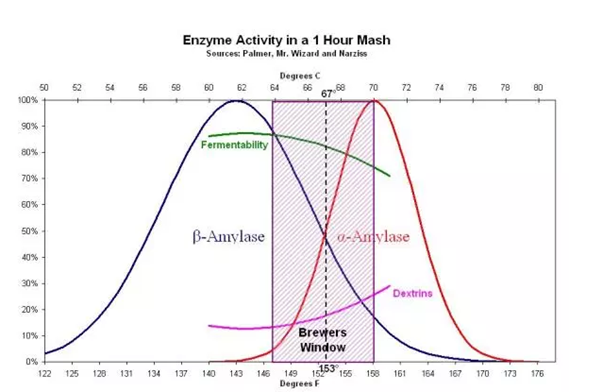

Since mashing grains at different temperatures promotes the activity of either alpha or beta amylase making more either fermentable or less fermentable sugars. the Grainfather recipe creator uses a ‘Brewers window’ which is between 62.5 and 72.50C. We then have a centre point in this range occurring at 67.50C any mash temp that is conducted in this range is then subjected to an adjustment factor based on if it is above or below 67.50C (below 67.5more fermentable, above 67.5 less fermentable).

Attenuation = Attenuation - 0.0225 x (lowest Mash Temperature - 67.5)

Based on the estimated FG will change significantly between 62 and 63 due to the edge of the brewer window being 62.5. The brewer's window is set at 62.5 due to the coefficient(+/- 50C) applied to the middle value of 67.5. The results of the different studies done by Michael Lewis and Tom young 2002 and Palmers (Lewis & Young,, 2002) (Palmer, 2017) work led us to use 62.5 as this was the midpoint in the edge between the two studies, this is also the same edge most other brewing software use.

As for the ‘time at different mash temperatures’ affecting fermentability. The calculations get complicated very quickly with multiple mash steps, so we try to keep it as simple as possible. with the use of highly modified malt and high proportions of high diastatic powered malts that allow for very quick conversion of starches, we use the mash step with the lowest temp in the range of 62.5˚C to 72.5˚C when calculating the FG. If a recipe has it's main mash step (Beta-amylase) just outside the range at 62˚C and, it's secondary mash step (Alpha-amylase) in the range at 72˚C. Then for this example, the calculation is run using the secondary mash step temp. However, by changing the first mash step to 63˚C then puts the primary step in range and the calculation for FG would be run off the primary mash step.

References

Daniels, R. (1996). Designing Great Beers. Boulder: Brewers Publications.

Lewis, M. J., & Young,, T. W. (2002). Brewing Second Edition . New York, Boston, Dordrecht, London, Moscow: Kluwer Academic / Plenum Publishers.

Palmer, J. J. (2017). How to Brew 4th Edition. Boulder: Kristi Switzer.